Free Flowing Exhaust: Unrestricted flow means unrestricted power.

Cut-outs: Unrestricted flow, but tuned length has changed = power band shifts (depending on length and diameter of pipe). This causes the "loss of low end torque" feeling.

Those examples above are two different tuning methods, and WILL effect torque.

Let's talk about engine mechanics first.

We have a camshaft which is GEARED to the crankshaft. There are VALVE EVENTS which occur at specified

degrees in relation to the crank position.

If you look at a cam card, you will see notes like:

EVO, EVC, IVO, IVC (etc.)

EVO = Exhaust Valve Open

EVC = Exhast Valve Close

You need to understand that these points NEVER

change no matter how fast the engine spins. You also need to realize that the exhaust pipes and headers CAN NOT change length as engine RPM changes (obviously).

This means that your INTAKE and EXHAUST pipes are

TUNED for ONE specific RPM.

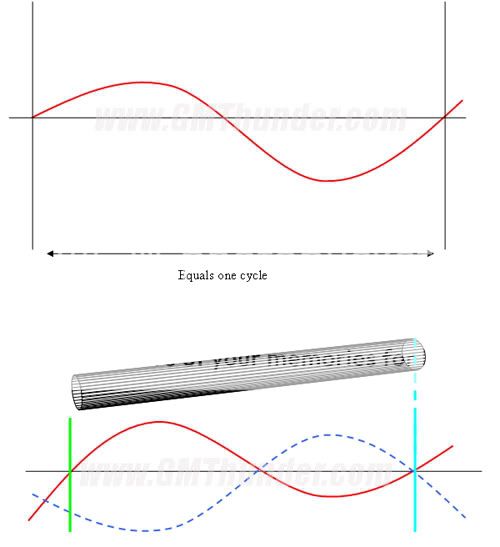

RPM changes which also changes the WAVELENGTH of

the PRESSURE PULSE.

Understand that an engine spinning at 1000 RPM

creates LESS pressure pulses than an engine spinning

at 6000 RPM.

Also understand at higher RPM these pulses must

happen FASTER in the same RELATIVE TIME (IE: PER MINUTE)

So...1000 pulses per minute have MORE TIME to happen than 6000 pulses per minute.

This means that higher RPM pulses have a SHORTER

wavelength (pulse length).

Anybody here with a basic understanding of audio

can relate short wavelength of high frequencies of a tweeter to long wavelength frequencies of bass tones of a sub woofer.

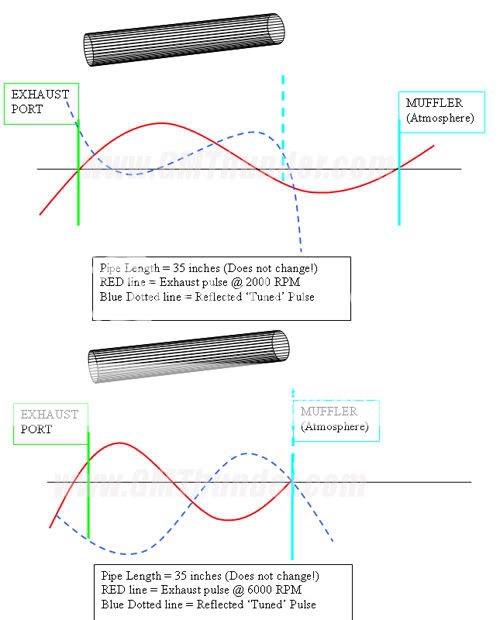

Think about your exhaust system. You are on the

DYNO and holding the engine at 2000 RPM.

The exhaust length is 65 inches and let's pretend

the pulse length is 65 inches.

In the diagram below you have a RED line which

indicates the pressure pulse as it EXITS the exhaust

port and travels the length of the exhaust pipe. When the pulse reaches the end of the pipe, it meets the atmosphere. When a moving object HITS another object there is a transfer of energy.

Think of a wave of WATER hitting a wall and bouncing

backward - air moves in a similar fashion. When the exhaust pulse hits the atmosphere it will reflect back toward the exhaust port. The dotted blue line represents this reflected wave - notice that the blue dotted line crosses the black line at, or below the axis.

This means the reflected pulse has reached the

exhaust port with LOWER PRESSURE.

Question One:

Will having a low pressure pulse reflect back

IMPROVE, or HURT the next exhaust pulse exiting?

Those who guessed that LOW PRESSURE will IMPROVE

the flow of the next pulse are CORRECT.

Here's why:

If you were water, or air exiting this exhaust pipe, would you find it easier to exit if there was a valley, or a hill?

The valley is the top scenario.

The hill is the bottom scenario.

Think of low pressure as a WEAK force. `Low` meaning

low force, or low resistance. When the exhaust valve is opening and the piston is pushing the waste out of the cylinder, the exiting pulse is HIGH pressure.

The exhaust gas will exit easier if there is little resistance

at the exhaust port. You can also think of low pressure as a VACUUM. It actually creates a sucking effect at the exhaust port so that when the valve opens, the low pressure area sucks the gas out of the cylinder.

Remember...fluids and gasses move from high pressure

to low pressure - that's a key point here.

So the reflected pulse is tuned to reach the port at LOW

pressure.

Now, what happens when you open your cut-out at 2000 RPM?

Have a look at the next diagram. Notice the top drawing has Engine RPM at 2000 RPM. The bottom has Engine RPM at 6000 RPM.

Think about what happens to the `EFFECTIVE LENGTH`

of your exhaust.

Things to think about:

Is the pipe tuned for a higher, or lower pulse now? The long RED wavelength is the exhaust pressure pulse @ 2000 RPM.

Question 3: At 6000 RPM with a shorter exhaust

pipe, (or cut-out open), will the torque be higher, or lower?

When you're talking about cutouts the distance is CRITICAL and will tune the exhaust to be efficient at ONE

RPM, with a tapering curve above and below that RPM. The RED wave in the top example extends beyond

the length of the pipe.

The WAVELENGTH/PRESSURE PULSE length at 2000 RPM

is LONGER than the TUNED LENGTH of the exhaust

pipe.

Now when you open the cut-out at 2000-3500 RPM

on the street, you notice a lack of POWER. People say "I lost BACKPRESSURE...That's Why I lost power!"

That is not true. By opening the cut out, you

have changed the tuning of the exhaust for the

RPM range you are using. Think about a pipe organ. Wonder why each note on the pipe organ has a DIFFERENT LENGTH of pipe?

"But why does the frequency of the exhaust decide how much power u make?"

It does not decide how much, but when the power

comes in. The pipe length in the exhaust has everything to do with how much power is made.

If you read up a few paragraphs you will see talk of

reflected pulses and exhaust pressure.

At 2000 RPM an exhaust pulse is 50 inches (for example). If we cut a pipe to be "resonant" at 2000 RPM, it would need to be 50 inches. This pipe would only be resonant at ONE RPM, and ONE frequency. The reflected pulse at 2000 RPM will reach the exhaust port and create a LOW PRESSURE area.

While the valves are opening and closing, the pulse

is reflecting back at 2000 RPM, everything is tuned

and resonant...which means it is highly efficient.

Someone driving around in the city would tune their

exhaust to this length because it would be more

efficient from 1000 to 3000 RPM with a PEAK at

around 2000 RPM (or somewhere in the middle).

When this guy goes racing, he opens his cut out. But today, he wants to open the cut out and drive around town. The pipe is now cut smaller in length. The tuned length is somewhere in the 5000 RPM range.

While he drives around at 2000 RPM, the exhaust

pressure pulses are still going to have a 50 inch

wavelength...but... The cut-out does not allow the reflected pulse to come back 180 degrees out of phase.

The reflected pulse returns at a higher pressure

at the port.

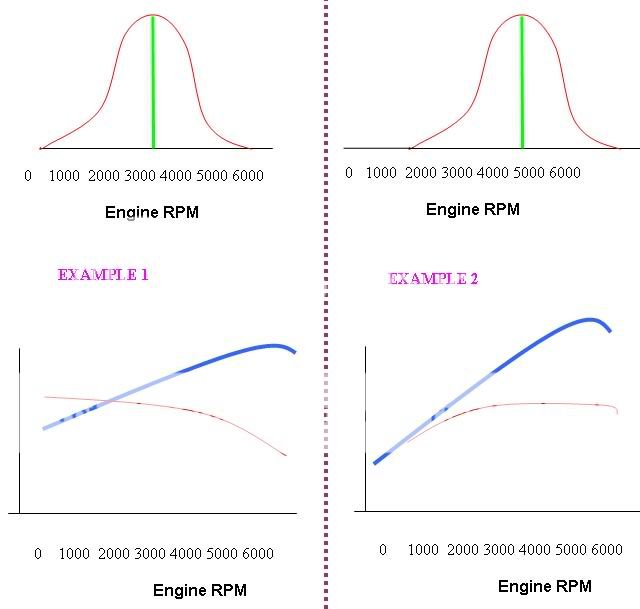

Check out this diagram:

Notice the top section on the left and right side.

There is a hump with a green line highlighting the

highest point of the hump. Also notice the RPM

at where the peak of the hump occurs.

Directly below each is a simulated torque and horsepower graph. Which side represents a tuned exhaust for a SHORT PIPE, or CUT OUT?

Answer: Example two!

Just remember it's not BACKPRESSURE that is causing the torque loss, it's all about the tuning - you need to select a pipe length that provides the best power curve in a window of RPM that the car requires.

Just like above, if you're going to be racing,

place the cut-out in a spot that improves the

resonant RPM to around 5000 RPM (like the right

side). On a Thirdgen Camaro/Firebird this would be right around the catalytic converter area.

Then everything above and below 5000 RPM will

taper off within your shift window (4000-6000 RPM).

Harrah's Cherokee Casino Resort selects Harrah's Cherokee

ReplyDeleteHarrah's Cherokee Casino 김포 출장마사지 Resort 통영 출장샵 selects Harrah's 청주 출장안마 Cherokee Casino Resort 목포 출장샵 to 구미 출장샵 feature world-class gaming, dining and entertainment at Harrah's Cherokee